|

09-10-2008, 09:32 PM

|

|

Chairman & Administrator

|

|

|

|

FG Falcon - Powertrain

FG Falcon - Powertrain

Ford Australia has developed a series of comprehensive upgrades for the engine line-up that will power the all-new FG Falcon range, including significant revisions to the six-cylinder engine family, along with a new V8 engine for the Falcon XR8.

The 2008 FG Falcon range also introduces two new transmissions - a new six-speed manual for all manual transmission variants and a new five-speed automatic, in lieu of the previous four-speed unit, on petrol sedans and utes.

"The latest generation of six-cylinder and V8 Falcon engines deliver the ideal combination of real world performance, driveability and fuel efficiency, while continuing to provide customers with a host of advanced features and technologies," Ford Australia Falcon & Territory Vehicle Line Director, Russell Christophers said.

"The comprehensive package of upgrades delivered with the all-new FG Falcon program has broadened the technological reach of the I6 and V8 engine families, building on the extensive engineering and development undertaken for BA and BF series Falcons.

"Power and torque have increased across all petrol engines, while improvements to engine refinement and fuel efficiency are also key components of the eighth generation FG Falcon range."

The new FG Falcon engine range encompasses 4.0-litre I6, 4.0-litre I6 Turbo, 4.0-litre I6

E-Gas and 5.4-litre Boss V8 powerplants.

4.0-litre I6 engine

The advanced design features of Ford's naturally aspirated 4.0-litre I6 engine have been expanded upon with the development of the latest generation powerplant, to again deliver more power, more torque and improved engine efficiency.

A new cylinder head, new intake manifold and revised engine calibration add to the list of existing high-tech features, such as double overhead cams, four valves per cylinder and dual independent variable camshaft timing (DIVCT), to produce Ford Australia's best in-line six-cylinder engine package yet.

Maximum power has increased by 5 kW to 195 kW at 6000 rpm, while the I6 engine continues to have the most torque in its class â and of any locally built, naturally aspirated six-cylinder engine â with peak torque up 8 Nm to 391 Nm at 3250 rpm, an advantage of more than 18 per cent compared to its direct competitor. "The latest generation I6 engine has tremendous torque and driveability, with a flat torque curve and wide power band at the top end as a result of all the new engine hardware and calibration developments that have been engineered for the FG Falcon program," Ford Australia Powertrain Engineering Manager, Lee Kernich said.

Additional performance and efficiency benefits can be obtained from using a higher octane, 95 RON unleaded fuel, liberating even more power and torque from the I6 engine, with peak power and torque outputs rising to 198 kW and 409 Nm respectively.

Courtesy of the engine's dual knock sensors and individual spark control, customers can obtain even further performance benefits from using 98 RON premium unleaded fuel.

Dual mode split plenum composite intake manifold

One of the key features of the engine is an all-new dual mode, split plenum composite intake manifold, incorporating a new electronic throttle body and fuel rail assembly.

The new manifold design increases peak power over the previous Barra 190 engine, as well as improving power delivery and driveability through enhanced responsiveness to throttle inputs. Other benefits include improved fuel efficiency and sound quality, and a 4kg weight reduction by virtue of using composite materials in lieu of an aluminium casting.

Using composite materials (the intake manifold utilises 30 per cent grade glass-filled nylon in its construction) also delivers driveability benefits over aluminium under heat soak conditions, due to its more efficient thermal qualities.

"The new design incorporates a manifold tuning valve in the main plenum, with a new configuration for the manifold runners," Kernich said.

"This dual mode, equal runner-length, system geometry has been tuned to achieve good low end torque and peak power characteristics, with smooth transitions at the valve switch points to achieve a high level of performance feel."

One of the core design challenges for this part of the project was to meet noise quality targets by focussing on sound quality rather than just absolute sound pressure levels in isolation.

"We were able to achieve this by tuning the intake manifold's geometry to produce a customer-preferred sound quality without compromising the desired power and torque characteristics," Kernich added.

"In fact, we were actually able to increase power and torque at the same time."

As a result of Ford's significant expertise in engine modelling and power-train design, the core manifold design was performed by Ford, while expertise in plastic manifold design and manufacturing was provided by the component supplier.

Fast burn cylinder head

The latest generation, FG series six-cylinder petrol engines (I6 and I6 Turbo) feature a new 'fast burn' cylinder head that delivers improvements in fuel efficiency on both engine variants. The redesigned cylinder head has revised intake port profiling and new combustion chamber geometry, which results in additional swirl within the combustion chamber for a faster burn rate.

"The higher turbulence enables additional camshaft retard at part throttle due to an improved lean limit, which further reduces pumping losses and improves fuel efficiency," Kernich said.

As a result, Brake Specific Fuel Consumption (BSFC) - which is a measure of an engine's efficiency - at part throttle cruise conditions has improved by approximately 1.5 per cent.

4.0-litre I6 Turbo

Ford's highly acclaimed 4.0-litre I6 Turbo engine gains the same cylinder head upgrade as the naturally aspirated I6 power plant, however, it also benefits from a multitude of turbo system improvements that deliver more power and torque, as well as improved responsiveness and fuel economy.

A new, higher efficiency Garrett turbocharger (developed specifically for Falcon) heads the list of engine developments, along with a host of other hardware and calibration upgrades that combine to produce the new I6 Turbo engine.

"The BA or BF-spec I6 Turbo engines could never be accused of exhibiting significant turbo lag characteristics, however, the new turbocharger responds 30 per cent faster again compared to the previous generation system," Kernich said.

"It has been optimised to operate in a higher efficiency range, which allows boost to come on quicker and therefore minimises turbo lag even further.

"Increased turbocharger boost pressure and a new, bigger intercooler with low restriction ducting also play a key role in delivering more power, more torque and improved performance feel."

Maximum turbocharger boost pressure has increased from 0.4 bar to 0.7 bar, or from 6 psi to 10 psi.

The new intercooler features a bar and plate construction for maximum heat rejection and minimum flow restriction. It improves the air charge cooling efficiency and effectiveness by increasing the density of the air charge, in turn enabling an increase in engine power.

With more boost pressure increasing the air charge being forced into the cylinders by the turbocharger, the new intercooler and ducting also deliver substantial gains by way of: ·a 50 per cent increase in intercooler core volume and size

·a 40 per cent improvement in heat rejection

·a 34 per cent reduction in flow restriction

The complete air induction system has been redesigned to reduce system flow restrictions and system volume, which results in increases to power and torque, as well as improving both engine responsiveness and overall fuel economy.

A new single runner intake manifold contributes to the improved torque delivery and engine responsiveness through the entire operating range, as well as a 36 per cent reduction in throttled volume and a 44 per cent reduction in component weight.

Tuned to complement the new, higher efficiency turbocharger in achieving an overall improvement in both low and high speed torque, the new intake manifold has also been designed to achieve the desired acoustic quality - just like the new dual mode, split plenum composite intake manifold on the naturally aspirated I6 engine.

The compression ratio has increased from 8.7:1 to 8.8:1, in line with the new fast burn cylinder head and combustion chamber geometry, which improves overall engine efficiency by increasing power and reducing fuel consumption, as well as part throttle driveability.

An all-new exhaust manifold has been tuned to minimise exhaust gas flow restriction into the turbocharger and optimise the flow balance from cylinder to cylinder.

More turbine power has been extracted out of the exhaust gas, resulting in enhanced turbo responsiveness and further minimisation of turbo lag.

The reduced internal surface area of the new exhaust manifold maximises heat transfer to the catalyst, improving engine emissions by heating the catalytic converter faster after cold start-up.

Overall, the new exhaust manifold has delivered: ·a 14 per cent reduction in flow restriction

·a 10 per cent improvement in flow balance

·a 42 per cent reduction in internal surface area

·a 36 per cent reduction in weight

The net result of all the turbo system improvements is a significant increase to peak power and torque outputs on the new I6 Turbo engine, along with new levels of engine responsiveness and considerable gains in terms of fuel economy and efficiency.

Maximum power is up by 25 kW to 270 kW at 5250 rpm, while peak torque has increased by 53 Nm (or more than 11 per cent) to 533 Nm, which is available across a wide rev range from 2000 rpm - 4750 rpm.

"With 80 per cent of the peak torque available all the way from 1250 rpm to 5750 rpm, the new I6 Turbo engine transforms the performance feel of our turbo models, delivering seamless power and fantastic responsiveness across all driving conditions," Kernich concluded.

Over boost & launch assist technology

The I6 Turbo engine features a number of new and unique performance features, which serve to expand the envelope of useable performance at both ends of the spectrum â maximising both standing start and in-gear performance.

While the calibration of the I6 Turbo engine has been optimised to improve fuel economy, it also incorporates a transient over boost feature, as well as launch assist and adaptive variable camshaft timing (VCT) anti-lag technologies.

"The transient over boost feature allows the engine to over boost by up to 10 per cent for several seconds, increasing available engine torque for improved performance during driving events such as overtaking manoeuvres," Ford Australia Powertrain Development Manager, David Mitchell said.

"Manual transmission turbo models are also equipped with a launch assist anti-lag feature, which increases available engine torque for more consistent maximum launch acceleration, as well as reducing turbo and exhaust temperatures, and minimising turbo lag and clutch wear."

During wide open throttle launches, positive boost pressures were previously not achievable to enable an optimum launch scenario.

The launch assist feature is activated when the vehicle is stationary - with clutch fully disengaged and requisite accelerator applied, engine speed is limited to a maximum of 3500 rpm by actively cutting fuel.

After a small delay of approximately 2-3 seconds, the turbo spools up with 80 per cent cool fresh air, which is pumped by the cylinders that have been deactivated. When the clutch is released and the vehicle starts to move away, all cylinders are reactivated and access to full torque is returned.

"The net result of the launch assist anti-lag feature is a more easily repeatable execution of a rapid and smooth launch, while at the same time increasing drive-train protection during such events," Mitchell said.

Adaptive Variable Camshaft Timing

The Dual Independent Variable Camshaft Timing (DIVCT) system on the I6 Turbo engine has been updated to improve turbo responsiveness, by employing adaptive characteristics via two separate cam timing strategies.

The primary VCT strategy has been optimised to balance maximum power and torque with overall fuel efficiency, while the secondary strategy has been optimised to deliver maximum engine and turbocharger response.

In normal driving and cruise scenarios the engine uses the base VCT strategy to maximise fuel efficiency while still providing maximum power and torque.

"During wide open throttle acceleration events, the engine switches to the secondary VCT strategy and adjusts cam angles in real time to minimise turbo lag and maximise engine response," Mitchell said.

"Once target turbo boost and engine performance levels have been achieved, the engine switches back to the primary VCT schedule."

Cylinder cut

The I6 Turbo engine also employs cylinder cut on gearshifts in automatic transmission vehicles, for improved shift timing and overall shift refinement.

The cylinder cut shift is performed in the following sequence:

* The transmission controller requests a torque reduction during the shift

* The engine controller decides how it will deliver this reduction via injector cut and spark retard

* The injectors are cut and the shift is completed

* The injectors are reactivated and normal engine operation resumes

The cylinder cut shift sequence is completed in approximately 0.25 of a second.

Shift times are reduced by more than 50 per cent on some gear-shifts, such as wide open throttle on the I6 Turbo, giving a sportier shift feel via the shorter, sharper gear-shifts.

The cylinder cut feature also enables better control of turbo boost pressure and smoother application of engine torque, which minimises any surge during gear-shifts.

Boss 290

A new V8 engine marks the transition from BF to FG for the Falcon XR8, with the introduction of the quad-cam Boss 290 power-plant to Ford's sports-performance XR range.

Supplied by Ford Australia's performance vehicle partner, Ford Performance Vehicles, each engine is hand-built from bare blocks and heads, with FPV adding a wide range of local upgrades and internal components.

Assembled on the only V8 production line in Australia, the Boss 290 engine features a number of unique FPV engine components: ·High performance, high compression pistons with domed tops lift the compression ratio to 10.5:1 for the Boss 290 (up from 9.5:1 for the Boss 260) for a major improvement in engine response and overall engine efficiency, particularly under light throttle loads.

·These high strength pistons feature a larger gudgeon pin, larger internal pillars to support the gudgeon pin and a special ring pack to match the high compression, extra power and torque loads.

·Sintered conrods for uniform weight and high strength, tailored to accommodate the larger gudgeon pin and to clear the larger gudgeon support pillars inside each piston - for significant gains in strength and durability.

·Forged steel crankshaft for exceptional refinement and strength under high power and torque loads - each Boss 290 crankshaft undergoes a special balancing process prior to assembly to match the new piston and conrod combination for reduced stress on engine components at all engine speeds.

·Cylinder heads are cast in aluminium alloy to minimise weight and to reach optimum operating temperature faster - they feature an improved Cobra R design with a straighter, better breathing inlet port for better performance.

·High-lift inlet camshaft that increases valve lift to 13 mm (10 mm in Boss 260) for improved inlet flow, fast response and easy-revving high performance feel.

·High-lift exhaust camshaft that increases exhaust valve lift to 12 mm (10 mm in Boss 260) for more efficient exhaust gas clearance.

·Longer valve stems and springs to match the high-lift camshafts for longer reach and improved gas flow in and out of the combustion chamber.

·Longer finger followers to match the higher cam profile and ensure accurate valve control through the extremities of valve lift.

·Locally-manufactured inlet manifold with tuned length trumpets to match the head design, delivering strong torque at lower engine speeds and power at high rpm.

·A larger-entry, free flowing air-box that provides more efficient airflow into the induction system, aiding performance and significantly reducing induction noise.

·A 75mm throttle body with drive-by-wire linkage, which eliminates the noise and vibration path that a mechanical linkage can generate as it enters the cabin. It reduces maintenance, allows more accurate throttle control and optional pedal adjustment on automatic models.

·Locally-manufactured, fabricated stainless steel exhaust headers for a total breathing package to match the performance inlet manifold, high-lift cam profiles and 32-valve heads.

·Engine blueprinting - a highly accurate three-grade engine tolerance system, measured in microns, matches crankshafts, pistons, blocks, conrods and bearings for a perfect fit. Accurate component matching by tolerances and weight delivers improved performance, refinement, durability and fuel efficiency.

The Boss 290 engine has also been equipped with a new oil pan, which has been designed to suit the new front structure design in the FG Falcon, along with new exhaust manifolds to suit the new body structure.

It also employs cylinder cut on gear-shifts in automatic transmission vehicles, for improved shift timing and overall shift refinement.

"Producing maximum power of 290 kW at 5750 rpm and 520 Nm peak torque at 4750 rpm, the Boss 290 takes the Falcon XR8 to the next level for V8 performance," said Ford Australia Power-train Engineering Manager, Lee Kernich.

"With an abundance of power and torque throughout the entire rev range, the Boss 290 also takes another step forward in terms of refinement and sophistication, integrating seamlessly with the FG Falcon program to transform the XR8 experience for customers."

Semi Active MufflerThe introduction of the Boss 290 engine to the XR8 is complemented by a revised exhaust system with an all-new Semi Active Muffler (SAM).

The SAM comprises a cylindrical valve that is mounted on the muffler end-plate protruding inside the intermediate muffler, which opens and closes to change the vehicle's exhaust sound characteristics.

At low engine speeds (low rpm), the spring loaded valve remains closed, forcing the exhaust gasses to pass through a series of baffles in the intermediate muffler.

At higher engine speeds (above 2800 rpm) the exhaust gas back pressure opens the valve, offering an alternate path for the exhaust gasses to pass through the muffler.

As a result the SAM provides a quiet internal cabin environment at idle and low engine speeds, while allowing a full, throaty V8 sound quality to be appreciated at higher engine speeds.

Typically, SAM valves have been the exclusive domain of high-priced, sports cars such as the Aston Martin V8 Vantage and Jaguar XK8, which both employ similar systems.

The semi-active muffler system on the XR8 is a first for the Australian auto industry in a locally-manufactured vehicle and delivers a best-in-class sound quality with an unsurpassed, sporty V8 exhaust note.

4.0-litre I6 E-Gas

Ford continues to offer an alternative fuel option on Falcon in the new FG range with the dedicated LPG six-cylinder E-Gas engine.

The E-Gas engine is carried over to the new model, following the extensive upgrade it received for the BF Falcon program, and is matched to the proven four-speed automatic transmission with Sequential Sports Shift (SSS).

For installation into the new FG Falcon architecture, new inlet and exhaust systems, a re-tuned throttle map and optimised engine calibrations have further refined the overall engine package and improved performance feel.

With dual independent variable camshaft timing (DIVCT), stronger conrods, and harder valves and seats for greater durability, the E-Gas engine produces 156 kW of power at 4750 rpm and 371 Nm of torque at 2750 rpm.

NEW MANUAL & AUTOMATIC TRANSMISSIONS

Two new transmissions have been introduced with the FG Falcon program, a new five-speed automatic in lieu of the previous four-speed unit on petrol sedans and Utes, and a new six-speed manual for all manual transmission variants.

"Both new transmissions deliver significant improvements to overall vehicle refinement, along with performance and driveability enhancements in a number of key areas," Ford Australia Powertrain Engineering Manager, Lee Kernich said.

"The five-speed auto has a wider spread of ratios than the outgoing four-speed design, which improves vehicle performance and offers a greater dynamic range.

"The new six-speed manual is a major upgrade of the previous T56 six-speed manual transmission and delivers improved shift feel and refinement, along with a number of clutch upgrades and enhancements for reduced pedal efforts and increased clutch durability."

New five-speed automatic

The 5R55S five-speed is a new rear-wheel drive (RWD) automatic transmission, which has been designed in conjunction with Ford engineers in the USA and is produced in Bordeaux, France, for use in the new FG Falcon.

It employs the Sequential Sports Shift (SSS) feature that has been a key design element on Falcon since the BA series was introduced in 2002, enabling the driver to choose an enhanced 'Performance mode' or have complete control of the transmission, for occasions when manual selection of gear ratios is preferred.

"The new transmission incorporates a unique main case and extension housing, a damper on the input shaft and the latest closed-shift loop controls," Kernich said.

"Numerous design features have also been incorporated in the five-speed automatic transmission, which enhance the outstanding engine characteristics of the 195 kW I6 powerplant."

Hardware

The entire transmission housing has been thoroughly analysed using advanced computer aided engineering (CAE) modelling techniques and designed to minimise radiated noise through structural optimisation.

Selected rotating components have controlled dynamic balance characteristics for smooth operation at any speed.

A high output trochocentric oil pump with flow control capability, directed lubrication system, dedicated oil to water transmission cooler and Mercon V super-premium synthetic blend fluid all contribute to outstanding durability through increased pump flow and lower operating temperatures.

The torque converter contains a high capacity dual friction plate bypass clutch, while the impeller and turbine blading are brazed for high speed shift stability and improved efficiency.

Gearing & software

With an additional gear and wider ratio spread (a 2.51 spread between first and top gears compared with 1.716 ratio spread on the four-speed auto) the new transmission delivers improved performance and more relaxed cruising, as well as a lower first gear ratio for enhanced launch feel.

Closed loop adaptive shift control on the five-speed auto ensures shift quality is both refined and consistent. During every gearshift, three speed sensors monitor shift duration and profile to achieve more consistent shift timing, while hydraulic pressure can be adjusted to optimise shift feel.

New shift strategy features on the five-speed auto include:

* Hunting prevention - this feature prevents unwanted upshifts based on torque and acceleration assessments.

* Grade lock in all gears - torque converter lock-up can be engaged in all gears, not just the top two gears, when high load conditions or a steep grade are detected, improving vehicle driveability as well as aiding transmission cooling and reducing fuel consumption.

An enhanced warm-up mode ensures the transmission will warm-up to its most efficient temperature operating range quickly, to provide optimum fuel efficiency. The transmission oil temperature is monitored at start-up and the shift schedule is adjusted to improve the transmission warm-up rate.

An increased capacity transmission oil cooler, in conjunction with an intelligent shift strategy, improves transmission oil temperature control, particularly during heavy towing, for greater durability and reliability.

As the oil temperature within the transmission increases, the shift strategy will use the optimum gears and a higher level of torque converter lock to minimise additional increases in oil temperature.

Performance mode features on the five-speed auto include:

* Back-out up-shift inhibit - when the throttle is released quickly (e.g. change of mind), instead of upshifting, the current gear is held for a certain period or until the throttle is re-applied. This prevents shift busyness, especially when cornering, and provides improved responsiveness when exiting the corner.

* Engine braking - engine braking is applied when the coast clutch is engaged, which improves vehicle control during descents.

* Downhill brake assist - when vehicle acceleration is present during braking, the transmission will invoke a downshift to provide increased engine braking, which also ensures the transmission is in the right gear for tip-in when the throttle is re-applied.

Specific transmission calibrations for the sedan and Ute allow for the sedan to be more performance-oriented, while the Ute has been optimised for its workhorse duties, such as carrying heavy loads and towing.

At the heart of the transmission's electronic control system is Ford's new 32-bit Powertrain Control Module (PCM), which integrates engine, transmission, cruise control and many other powertrain control functions to provide smooth and responsive powertrain performance.

New six-speed manual

The new Tremec TR6060 six-speed manual transmission is a major upgrade of the previous T56 six-speed manual transmission and is now fitted to all manual transmission variants in the FG Falcon range - replacing both the T5 five-speed manual on previous XL and XLS Ute models, as well as the T56 six-speed manual on XR sedans and Utes.

There a three variants of the TR6060 transmission - I6 engine (Falcon Ute/Falcon XR6), I6 Turbo engine (XR6 Turbo) and V8 (XR8). The XR6 Turbo and XR8 have a different set of ratios to the Ute/XR6 models, for improved performance and a more defined sports feel.

"With all manual transmission Falcon models now equipped with six forward gears, driving range improvements, and the reduced engine speed that comes from the additional overdrive gear, are now key benefits that apply across the range," Kernich said.

"Revised fifth and sixth gear ratios on all manual transmissions has improved NVH and highway-cruise efficiency via the reduced engine speed for a given road speed in those gears.

"Also included in the range of developments on the new manual transmission is a new synchroniser package, which provides improved shift precision and shift feel, and reduced shift effort and travel."

The new synchroniser package features triple synchromesh on first and second gears, and double synchromesh on all other gears, including reverse, which has significantly reduced gear shift efforts and shift travel.

The reduced shift travel provided by the synchroniser package has also allowed increased space for the use of larger gears, which are stronger to deliver improved torque capacity and gearbox durability.

A new single-piece countershaft also contributes to the greater torque capacity and durability advancements.

The XR6 Turbo has a larger clutch housing to accommodate an increase in clutch size, as well as a revised first gear ratio - a shorter 2.98:1 ratio replaces the 2.66:1 ratio in the T56 gearbox - for improved acceleration, launch feel and gradeability.

Other features of the new TR6060 transmission include:

* Reduced friction in the shifter system courtesy of a new cam and anti-friction plunger to control the side load shift detents.

* Forward and rearward shift detent grooves are broached on the front of the main-shaft with a spring-loaded anti-friction roller, for more precise control of the shift detents and a more positive shift feel.

* Anti-friction ball struts, sintered hubs and fine-pitch splines on all synchronisers for reduced friction between components - delivering improved shift feel and reduced shift efforts.

* Wider, two-piece gears with machined clutch teeth for more precise gear engagement and reduced potential for gear block-outs.

Self-adjusting clutch

A new, larger 290mm diameter single plate, self-adjusting type clutch has been developed for FG Falcon XR6 Turbo and XR8 applications - the XR6 Turbo previously employed a conventional 267mm diameter clutch unit, while the XR8 was fitted with a 280mm diameter clutch.

The new clutch provides a significant increase in thermal and torque capacities on both models, for improved wear life and durability.

The clamp load of the new clutch has been increased for improved clutch torque capacity, while the addition of a clutch pedal assist spring on both XR6 Turbo and XR8 acts to reduce clutch operating efforts for increased driving comfort.

The over-centre spring on the clutch pedal provides assistance as the clutch pedal is operated, as well as the effort required to hold the clutch pedal in a depressed position.

All manual transmission Falcon models are now fitted with a self-adjusting clutch (SAC), as the new unit ensures consistent pedal efforts over the life of the clutch.

While conventional clutches change as the disc wears, resulting in increased clutch pedal efforts, with a self-adjusting type unit, the clutch self-compensates for disc wear and ensures release efforts do not increase over time.

Powertrain Control Module

A comprehensively updated Powertrain Control Module (PCM) has been introduced across the FG Falcon engine program, to match the host of new powertrain features now available on the various Falcon models, including:

* New five-speed automatic transmission

* New intake manifold tuning valve

* New pedal box

* New, high-powered ignition coils

* One-touch start

* New cluster display

* Set-Point cruise

* Run on fans

* Modified software features to improve driveability

A one-touch start feature has been introduced on all petrol models fitted with an automatic transmission, which improves the consistency of start-up.

If the driver lets go of the ignition key before the engine has fully started, the PCM ensures the start operation is completed. In previous models, releasing the key before the engine had a chance to catch could lead to a start-run-stall scenario - the one-touch start feature alleviates this condition.

Additional information messages are available in the new instrument cluster display, including cruise control set speed, which provide more information to the driver about vehicle operation.

The cruise control system on FG Falcon has a new set speed indexing feature to suit the new cruise set speed display in the instrument cluster, which gives the driver the ability to know what cruise set speed has been selected both prior to and during cruise control operation.

The new cruise control system uses classical control algorithms and new model-based calculations to improve the accuracy and speed of its torque calculations under all conditions, allowing the driver to quickly change the cruise set speed to a new speed.

The new cruise control system provides:

* Improved speed regulation across all terrains

* Unobtrusive, smooth and progressive torque changes in varying terrains, and between all cruise control operating modes

A new engine cooling fan 'run-on' strategy allows the PCM to determine if it needs to run the engine fans for a short time after the engine is shutdown (under extreme temperature conditions) to reduce the risk of coolant loss and extend the life of engine bay components.

The feature offers heat soak protection by reducing susceptibility for coolant to boil on shutdown after sustained high load towing or high speed operation, combined with high ambient temperatures.

Modifications to software features have delivered driveability improvements on manual and automatic transmission vehicles, along with more advanced failsafe operations to improve useability in the event of a malfunction.

Neutral / drive detection is improved on manual transmission vehicles through modelling of transmission gear ratios, resulting in greater engine stability on coast downs, as well as smoother torque transitions during slow speed events such as car park manoeuvres.

Driveability is also improved via reduced shunts and shuffles through the driveline, while on automatic transmission vehicles, idle stability improvements have contributed to smoother gearshifts.

Fuel system

Upgrades to the fuel system on FG Falcon have resulted in a number of key developments, including the introduction of redesigned fuel tanks on all Falcon models, a new and larger fuel tank on Falcon Ute models, a contactless fuel sender and revised software calibration.

The fuel tank redesign accommodates a blow moulding process for the tank construction, instead of the thermo forming process used previously.

The overall tank package has been optimised at the same time to maximise useable tank volume, while the Falcon Ute fuel tank has increased in total volume to 81 litres, up from 75 litres in the previous model.

A new, non-contact fuel sender has been introduced with the upgraded fuel system, with the electrical contacts packaged in a sealed unit to prevent contamination by sulphur compounds typically found in Australian fuel.

As the sender signals are now more consistent (and more consistent over time) the interpretive software controlling fuel gauge and trip computer functions provides a more accurate assessment of remaining fuel, so customers can confidently drive to the full range of the fuel tank.

The trip computer uses information directly from the new PCM to calculate fuel usage, which improves the accuracy of 'distance to empty' calculations.

MORE PERFORMANCE & IMPROVED FUEL ECONOMY

In addition to the widespread performance gains achieved on six-cylinder and V8 petrol engines with the all-new FG Falcon range, Ford Australia has also delivered further improvements to fuel economy on a number of key sedan powertrains.

The introduction of new manual and automatic transmissions, along with a host of new engine hardware and calibration developments, has resulted in fuel economy improvements on select Falcon models of more than six per cent.

"Fuel economy and engine performance are traditionally divergent areas, where you wouldn't expect to be able to improve one without it being at the expense of the other," Ford Australia Falcon & Territory Vehicle Line Director, Russell Christophers said.

"But our customers have told us they wanted improvements in both performance and fuel economy, and they were not willing to trade.

"With the new FG Falcon range we have delivered exactly that - more performance and better fuel economy on the I6 engine, and more performance and better fuel economy on the I6 Turbo engine.

"The introduction of the Boss 290 V8 engine to the XR8 has also delivered more performance, as well as better fuel economy compared to the BF MkII FPV GT from which it is derived."

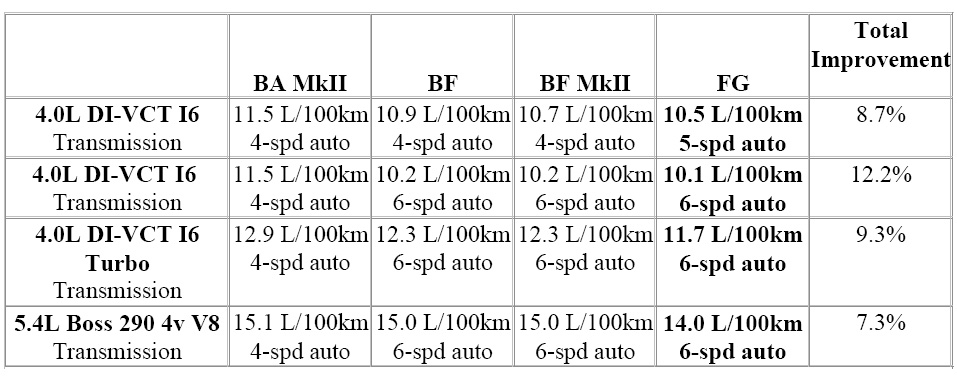

Fuel economy on the new 195 kW I6 engine with the new five-speed auto transmission has improved by 0.2 L/100km, or almost two per cent, compared to its predecessor (the Barra 190 I6 engine with four-speed automatic transmission) with an official Australia Design Rule (ADR) ADR 81/01 industry standard fuel consumption figure of 10.5 L/100km.

The I6 engine matched to the ZF six-speed automatic transmission remains the fuel economy leader within the Falcon range, with a further one per cent improvement (or a reduction of 0.1 L/100km) on FG Falcon to 10.1 L/100km.

Fuel economy on the new I6 Turbo engine has improved significantly as a result of the extensive engine development program undertaken for the FG Falcon, which has delivered 10 per cent more power and 11 per cent more torque, with a 4.9 per cent improvement in overall fuel economy.

The new 270 kW I6 Turbo engine, coupled with the ZF six-speed automatic transmission, produces an ADR 81/01 fuel figure of 11.7 L/100km, a reduction of 0.6 L/100km on the equivalent BF-spec powertrain.

The introduction of the 5.4-litre Boss 290 V8 engine to the FG Falcon XR8, in conjunction with optimised calibrations on the high-performance powerplant, has delivered a 6.7 per cent improvement in fuel economy.

The official ADR 81/01 fuel figure for the new V8 engine, matched to the ZF six-speed automatic transmission, is down 1.0 L/100km to 14.0 L/100km.

The new FG Falcon models continue the process of ongoing engineering development and refinement, which has delivered fuel economy improvements of more than 12 per cent on some powertrains over the past five years. During that time, the company has responded to customer demand with a dramatic improvement in fuel economy on its petrol engines, particularly the mainstream 4.0-litre I6 engine that is used in the majority of Falcon and Falcon Ute models.

|

Posting Rules

Posting Rules

|

You may not post new articles

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Be The First